I woke up from a nap to a loud pop and a smell of burning plastic. The source turned out to be one of the most precious and important to me digital devices: a ReadyNAS NV+, a small silver box with over a terabyte of hard drives that store my backups, music, and photos.

Network attached storage (NAS) is an engineering compromise. It’s a storage solution that lets you keep a bunch of drives in a self-contained device. It’s redundant: you can lose a drive (which is a statistical certainty) and not lose your data. There are also handy usb ports that let you connect usb drives and a button to run backup jobs onto these drives. It also serves as a print server, and in theory it can be used as a streaming media server. On the other hand it’s slow (gigabit networks are not fast enough when you need gigs of data fast), a complete nightmare to use with photo managers like Picasa, and an even worse nightmare if you want to use it as a Time Capsule.

I’ve spent a lot of time babysitting my ReadyNAS NV+: changing the defective RAM that it shipped with, updating the buggy firmware, finding the right drives for it (some don’t have the right temperature sensors). Don’t get me started on what it took to make it work with Mac’s Time Machine.

And after all that, the one box that was supposed to keep my precious digital archives safe was smoking. This was preceeded by a few days of weird performance issues and a couple of hangs. The power supply finally died a horrible death, and I realized that once again I was falling victim (or “mugu” as Nigerians say) to faulty capacitors.

According to Wikipedia, the name of this phenomenon is “Capacitor Plague“. There is an epidemic of failure in electrolytic capacitors from certain shady manufacturers. Electrolytic capacitors are usually found in power supplies. They are little aluminum cylinders filled with special film and electrolytic liquid or gel. Power supplies get very hot, and the liquid part of the capacitors, the electrolyte, always wants to either dry up or explode. The formula for the electrolyte is very hard to get right.

The rumor is that one or a few companies resorted to industrial espionage to steal electrolyte formulations. They weren’t entirely successful – they either got an incomplete formula or just plain Brawndo.

Spectrum Online did some digging:

“According to the source, a scientist stole the formula for an electrolyte from his employer in Japan and began using it himself at the Chinese branch of a Taiwanese electrolyte manufacturer. He or his colleagues then sold the formula to an electrolyte maker in Taiwan, which began producing it for Taiwanese and possibly other capacitor firms. Unfortunately, the formula as sold was incomplete.

“It didn’t have the right additives,” says Dennis Zogbi, publisher of Passive Component Industry magazine (Cary, N.C.), which broke the story last fall. According to Zogbi’s sources, the capacitors made from the formula become unstable when charged, generating hydrogen gas, bursting, and letting the electrolyte leak onto the circuit board. Zogbi cites tests by Japanese manufacturers that indicate the capacitor’s lifetimes are half or less of the 4000 hours of continuous ripple current they are rated for.”

Wastefulness of today’s society masks the problem: most people don’t perform autopsies on their dead $70 DVD players or $500 computers, they just use that as an excuse to buy the new hottness. The techies with (or without) spare time and soldering skills do the following: fill bulleten boards with tales of saving their devices by soldering in new capacitors; search for instructions on how to solder and purchase capacitors; and curse creatively after doing it for the 5th time.

The unique thing about the capacitor plague is how easy it is to identify: the capacitors literally blow their tops, venting electrolyte through the special stress relief indentations. It’s also unique in that anybody with a soldering iron has a very good chance of fixing it: the caps are easy to locate and solder. In the age when most electronic components are of the “surface mount” type (the size of a sesame seed) or chips with dozens legs as fine as silk, soldering in a two legged capacitor is very refreshing.

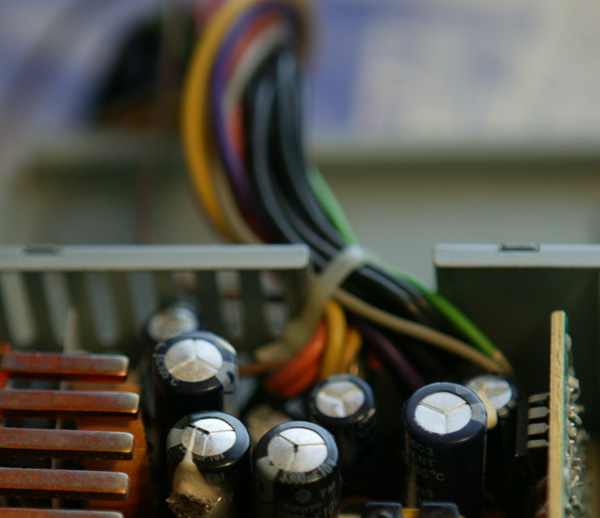

Here’s a nest of capacitors from my busted power supply: two in the left corner are clearly popped, the one on the right is probably ok:

In the last couple of years the following devices that I own fell prey to faulty caps: a cheap off-brand dvd player, a speed control on my Dodge Caravan’s air conditioner, a Netgear network hub, a huge and expensive Air King window fan, and now, my ReadyNAS. The interesting thing is that the problem exists in both high end and low end products, as well as in high tech and low tech ones (I did not know there were electronic components in the window fan).

I am out of warranty on my ReadyNAS because I bought it in May of 07. The following passage leads me to believe that the shitty capacitors are a problem that they are aware of and (maybe) fixed in newer releases of the hardware (they could not offer a 5 year warranty if they used the same capacitors – they’d just go broke).

“Please be aware that ReadyNAS purchased prior to August 21, 2007 carries a one-year limited warranty. Extended warranty purchased for these ReadyNAS will be honored by NETGEAR. ReadyNAS NV+ and 1100 purchased August 21, 2007 and later have a 5-year limited warranty, and the ReadyNAS Duo has a 3-year warranty.”

The brand name of the popped capacitors reads “Fuhjyyu”. It lead me to the an urban dictionary entry that says that Fuhjyyu is either

“1) Chinese word for feces.

or

(2) Brand name of abysmal quality capacitors that are installed on logic boards, switching power supplies and various other electronic components.”

There’s also a post from a guy who implores ReadyNas to stop using those capacitors.

Then there’s badcaps.net – a global capacitor gripefest that is too depressing to read.

You can see a nice gallery of busted caps over here

There are broader implications of this: coupled with the fragile lead free solder, leaky capacitors don’t only cause kajillions of dollars of damage, but will also make electronics of our era impossible to use in the near future. The aluminum in burnable cds and dvds are rotting too, destroying the record of our time.